|

This is a very interesting project with

many practical applications in security and alarm

systems for homes, shops and cars. It consists of a set

of ultrasonic receiver and transmitter which operate at

the same frequency. When something moves in the area

covered by the circuit the circuits fine balance is

disturbed and the alarm is triggered. The circuit is

very sensitive and can be adjusted to reset itself

automatically or to stay triggered till it is reset

manually after an alarm.

As it has already been stated the

circuit consists of an ultrasonic transmitter and a

receiver both of which work at the same frequency. They

use ultrasonic piezoelectric transducers as output and

input devices respectively and their frequency of

operation is determined by the particular devices in

use.

The transmitter is built around two NAND

gates of the four found in IC3 which are used here wired

as inverters and in the particular circuit they form a

multivibrator the output of which drives the transducer.

The trimmer P2 adjusts the output frequency of the

transmitter and for greater efficiency it should be made

the same as the frequency of resonance of the

transducers in use. The receiver similarly uses a

transducer to receive the signals that are reflected

back to it the output of which is amplified by the

transistor TR3, and IC1 which is a 741 op-amp. The

output of IC1 is taken to the non inverting input of IC2

the amplification factor of which is adjusted by means

of P1. The circuit is adjusted in such a way as to stay

in balance as long the same as the output frequency of

the transmitter. If there is some movement in the area

covered by the ultrasonic emission the signal

that is reflected back to the receiver

becomes distorted and the circuit is thrown out of

balance. The output of IC2 changes abruptly and the

Schmitt trigger circuit which is built around the

remaining two gates in IC3 is triggered. This drives the

output transistors TR1,2 which in turn give a signal to

the alarm system or if there is a relay connected to the

circuit, in series with the collector of TR1, it becomes

activated. The circuit works from 9-12 VDC and can be

used with batteries or a power supply.

Click Here to View

Circuits

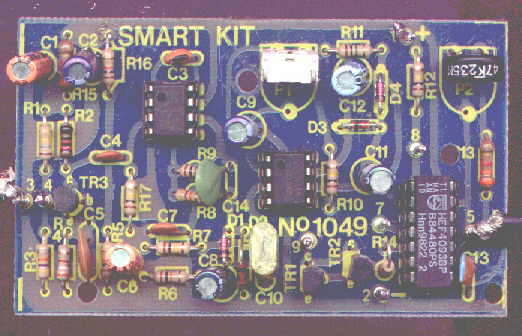

First of all let us consider a few

basics in building electronic circuits on a printed

circuit board. The board is made of a thin insulating

material clad with a thin layer of conductive copper

that is shaped in such a way as to form the necessary

conductors between the various components of the

circuit. The use of a properly designed printed circuit

board is very desirable as it speeds construction up

considerably and reduces the possibility of making

errors. Smart Kit boards also come pre-drilled and with

the outline of the components and their identification

printed on the component side to make construction

easier. To protect the board during storage from

oxidation and assure it gets to you in perfect condition

the copper is tinned during manufacturing and covered

with a special varnish that protects it from getting

oxidised and also makes soldering easier. Soldering the

components to the board is the only way to build your

circuit and from the way you do it depends greatly your

success or failure. This work is not very difficult and

if you stick to a few rules you should have no problems.

The soldering iron that you use must be light and its

power should not exceed the 25 Watts. The tip should be

fine and must be kept clean at all times. For this

purpose come very handy specially made sponges that are

kept wet and from time to time you can wipe the hot tip

on them to remove all the residues that tend to

accumulate on it. DO NOT file or sandpaper a dirty or

worn out tip. If the tip cannot be cleaned, replace it.

There are many different types of solder in the market

and you should choose a good quality one that contains

the necessary flux in its core, to assure a perfect

joint every time. DO NOT use soldering flux apart from

that which is already included in your solder. Too much

flux can cause many problems and is one of the main

causes of circuit malfunction. If nevertheless you have

to use extra flux, as it is the case when you have to

tin copper wires, clean it very thoroughly after you

finish your work. In order to solder a component

correctly you should do the following:

@Clean the component leads with a small

piece of emery paper.

@Bend them at the correct distance from

the components body and insert the component in its

place on the board.

@You may find sometimes a component with

heavier gauge leads than usual, that are too thick to

enter in the holes of the p.c. board.

@In this case use a mini drill to

enlarge the holes slightly. Do not make the holes too

large as this is going to make soldering difficult

afterwards.

@Take the hot iron and place its tip on

the component lead while holding the end of the solder

wire at the point where the lead emerges from the board.

The iron tip must touch the lead slightly above the p.c.

board.

@When the solder starts to melt and flow

wait till it covers evenly the area around the hole and

the flux boils and gets out from underneath the solder.

The whole operation should not take more than 5 seconds.

Remove the iron and allow the solder to cool naturally

without blowing on it or moving the component. If

everything was done properly the surface of the joint

must have a bright metallic finish and its edges should

be smoothly ended on the component lead and the board

track. If the solder looks dull, cracked, or has the

shape of a blob then you have made a dry joint and you

should remove the solder (with a pump, or a solder wick)

and redo it.

@Take care not to overheat the tracks as

it is very easy to lift them from the board and break

them.

@When you are soldering a sensitive

component it is good practice to hold the lead from the

component side of the board with a pair of long-nose

pliers to divert any heat that could possibly damage the

component.

@Make sure that you do not use more

solder than it is necessary as you are running the risk

of short-circuiting adjacent tracks on the board,

especially if they are very close together.

@When you finish your work cut off the

excess of the component leads and clean the board

thoroughly with a suitable solvent to remove all flux

residues that may still remain on it.

@There are quite a few components in the

circuit and you should be careful to avoid mistakes that

will be difficult to trace and repair afterwards. Solder

first the pins and the IC sockets and then following if

that is possible the parts list the resistors the

trimmers and the capacitors paying particular attention

to the correct orientation of the electrolytic.

@Solder then the transistors and the

diodes taking care not to overheat them during

soldering. The transducers should be positioned in such

a way as they do not affect each other directly because

this will reduce the efficiency of the circuit. When you

finish soldering, check your work to make sure that you

have done everything properly, and then insert the ICs

in their sockets paying attention to their correct

orientation and handling IC3 with great care as it is of

the CMOS type and can be damaged quite easily by static

discharges. Do not take it out of its aluminium foil

wrapper till it is time to insert it in its socket,

ground the board and your body to discharge static

electricity and then insert the IC carefully in its

socket. In the kit you will find a LED and a resistor of

560 which will help you to make the necessary

adjustments to the circuit. Connect the resistor in

series with the LED and then connect them between point

9 of the circuit and the positive supply rail (point 1).

Connect the power supply across points 1

(+) and 2 (-) of the p.c. board and put P1 at roughly

its middle position. Turn then P2 slowly till the LED

lights when you move your fingers slightly in front of

the transducers. If you have a frequency counter then

you can make a much more accurate adjustment of the

circuit. Connect the frequency counter across the

transducer and adjust P2 till the frequency of the

oscillator is exactly the same as the resonant frequency

of the transducer. Adjust then P1 for maximum

sensitivity. Connecting together pins 7 & 8 on the p.c.

board will make the circuit to stay triggered till it is

manually reset after an alarm. This can be very useful

if you want to know that there was an attempt to enter

in the place which are protected by the radar.

This kit does not need any adjustments,

if you follow the building instructions.

If they are used as part of a larger

assembly and any damage is caused, our company bears no

responsibility.

While using electrical parts, handle

power supply and equipment with great care, following

safety standards as described by international specs and

regulations.

Check your work for possible dry joints,

bridges across adjacent tracks or soldering flux

residues that usually cause problems. Check again all

the external connections to and from the circuit to see

if there is a mistake there.

See that there are no components missing

or inserted in the wrong places.

Make sure that all the polarised

components have been soldered the right way round. Make

sure that the supply has the correct voltage and is

connected the right way round to your circuit. Check

your project for faulty or damaged components.

If everything checks and your project

still fails to work, please contact your retailer and

the Smart Kit Service will repair it for you.

|

|

| R1 = 180 KOhm |

C1, 6 = 10uF/16V TR1 |

2, 3 = BC547 , BC548 |

| R2 = 12 KOhm |

C2 = 47uF/16V |

P1 = 10 KOhm trimmer |

| R3, 8 = 47 KOhm |

C3 = 4,7 pF |

P2 = 47 KOhm trimmer |

| R4 = 3,9 KOhm |

C4, 7 = 1 nF |

IC1, 2 = 741 OP-AMP |

| R5, 6, 16 = 10 KOhm |

C5 = 10nF |

IC3 = 4093 C-MOS |

| R7, 10, 12, 14, 17 = 100 KΩ |

C8, 11 = 4,7 uF/16V |

R = TRANSDUCER 40KHz |

| R9, 11 = 1 MOhm |

C9 = 22uF/16V |

T = TRANSDUCER 40KHz |

| R13, 15 = 3,3 KOhm |

C10 = 100 nF |

D1, 2, 3, 4 = 1N4148 |

| |

C12 = 2,2 uF/16V |

|

| |

C13 = 3,3nF |

|

| |

C14 = 47nF |

|

|