|

Capacitance Probe

A simple probe can be made using

insulated wire. The insulation is then the dielectric of

an annular capacitor with the inner conductor as one

plate and the water as the other. The probe is not

suitable for distilled or very pure water because it is

not conductive enough. It works well even in relatively

clean water such as roof runoff water in a plastic tank.

PVC plastic coated multistrand hookup wire will work but

is porous and may eventually give trouble. Better to use

the PTFE (teflon) equivalent. Enamelled copper wire

gives a high capacitance per unit length because the

insulation is very thin and this is suitable for short

probes of up to about 200mm. For long probes a pipe with

a sliding clamp to tension a single wire works well.

Keep the wire away from the pipe to avoid turbulence

effects. The problem with a single wire is sealing the

end under water, especially the PTFE type. It is better

to make a loop to form a U shape so that both ends are

out of the water, of course only one end needs to be

connected to the electronics, with the metal frame being

the other connection to the electronics common and to

the water. A side benefit is that the capacitance per

unit length is doubled but in the case where the probe

is being used to measure wave height it must be aligned

so that both arms of the wire are normal to the wave,

otherwise an error could result. Light springs can be

used at the top to maintain wire tension. Make sure

there are no sharp edges at the bottom of the U where

the wire is held to the frame.

The probe needs to be attached to

something fixed like the side or top of a water tank, or

to a pier. If the water depth is not too great a stake

can be driven into the bottom of a river or dam and the

probe attached to it.

The electronics should be above water in

a waterproof box that is attached to the metal probe

frame. The box cannot be separated some distance away

from the probe because the capacitance of a cable would

be too great compared to the probe capacitance. The

output cable can also bring low voltage unregulated DC

power to the unit. It can be long and even be under

water back to dry land if required.

Electronics Units

A simple analog unit can be made using a

LM324 quad op. amp.

One op. amp is configured as a 5kHz

oscillator and a fraction of the output from it is fed

to the non-inverting input of a second op amp. This is

configured as a non-inverting stage with the probe

connected to the inverting input and ground and a

"range" capacitor connected from the output back to the

inverting input. The output level from this stage starts

at the same as the input level and goes up with wave

height or depth. Two 10M ohm resistors in series are

placed across the range capacitor to reduce 50Hz/60Hz

pickup.

The output is high pass filtered and

rectified to DC. The third op. amp is a differential

stage that subtracts the rectified DC from the output

from a potentiometer connected to +5V for zero

adjustment. The output from this stage is low pass

filtered to 20Hz and the final op. amp is a

non-inverting stage with amplification.

Total current from a 9V battery using

+5V and -5V micropower regulators together with a

ICL7662 charge pump inverter is about 1.8mA.

Output is in the range of +/- 3.5 volts.

The capacitance probe is connected to an

ICM7555 running in astable mode. The 7555 has the

advantage as an oscillator for this application because

the capacitor is grounded. The resistor values are

chosen so that the minimum frequency is above 5kHz. The

minimum occurs at the maximum water level.

The probe and it's connections have some

capacitance out of water and will determine the maximum

frequency. The ICM7555 has a maximum frequency of about

500kHz.

The period of oscillation is

proportional to the capacitance and therefore to the

water level. The period is measured using the

timer/counters of a microcontroller, the Microchip PIC

16F876. The output of the ICM7555 is connected to pin

RA4 which is timer 0 clock input via a prescaler.

Timer 0 byte is preloaded with a value

and an interrupt is generated when it overflows. A fixed

number of 7555 pulses are therefore counted.

There is some jitter in the 7555

frequency so it is necessary to count a large number of

pulses to get the average period. One thousand is

sufficient, but it is a tradeoff. For tank water level

measurement the time taken can be long but for wave

measurement it is necessary to have a higher overall

sample rate.

The time taken for timer 0 to overflow

is measured by the 16 bit timer 1 counting the crystal

frequency divided by four. The crystal is 4MHz so the

value in timer 1 is in microseconds. Any overflows of

timer 1 are counted by counting the overflow interrupts.

The two resistors needed on the 7555 are

both 21k ohm and are low temperature coefficient types

from the RC55 series from Farnell or equivalent. They

have coefficients of 15 parts per million per degree C.

The Philips ICM7555 itself has a temperature coefficient

of around +0.02% per degree C. This means that for a

depth of 2000 mm and a 50 deg C. temperature change on

the 7555, the output will change by 20 mm. Depending on

the application, this may be a significant error.

In the present unit the ambient

temperature near the 7555 is measured using a digital

temperature sensor, the Dallas DS1624, and the measured

temperature is used to immediately correct the 7555

period measurement to that at a reference temperature of

0 deg C. The correction can be set for a particular 7555

for best results because there is some variation in the

temperature coefficients.

The timer 1 count is scaled to

millimetres and output to the RS232 serial port in ASCII

format so that the data can be viewed and saved to a

file using a terminal program such as Hyperterminal in

Win 95/98. Temperature is also output with a resolution

of 0.1 deg C. and accuracy of 0.5 deg. C.

A photo of the prototype board hooked up

to a rainwater tank.

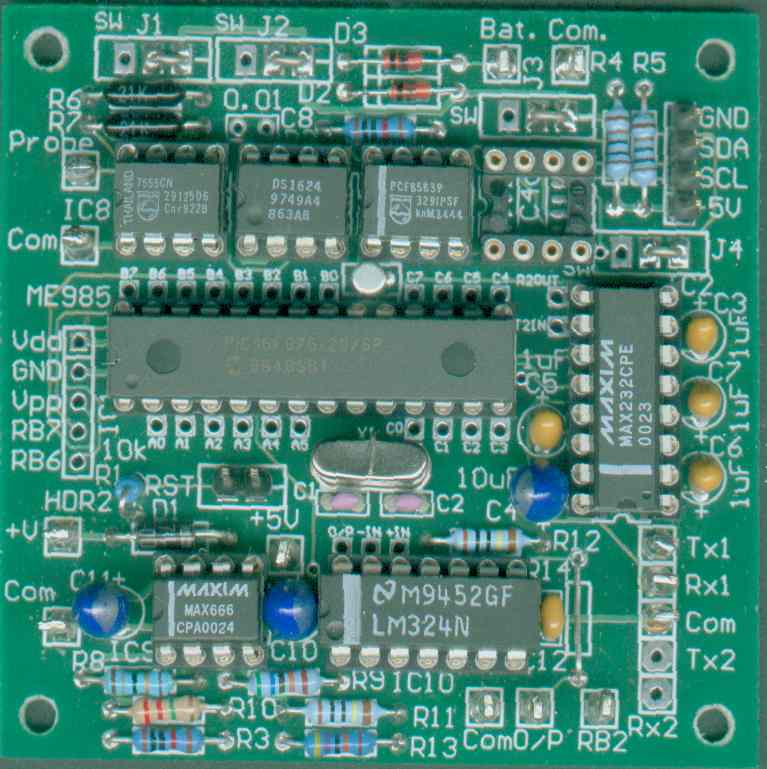

A photo of the complete board.

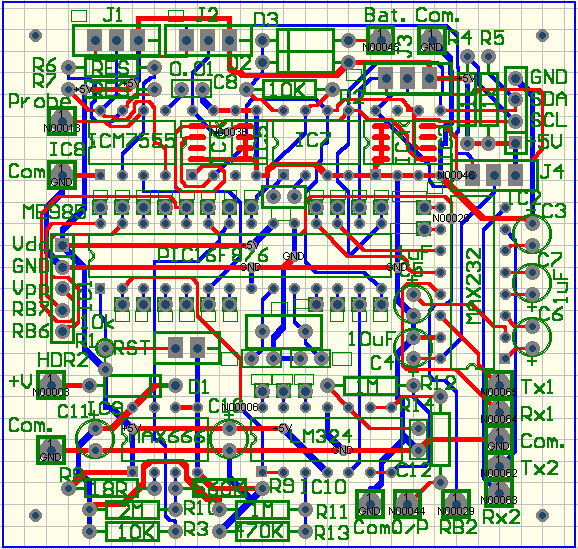

Layout of PCB.

There are Protel files for a printed

circuit board for this unit. The board is

67mm by 64mm.

In addition to the 7555, 16F876, and

DS1624 chips mentioned earlier the board has provision

for components that may be omitted for some applications

that dont need them.

Where a component is available with

dual-in-line pins as well as in surface mount both

footprints are provided, one within the other.

The Philips PCF8583 IIC bus

clock/calendar chip can be used to date/time stamp the

level and temperature data. Also, the alarm output is

connected to the external interrupt pin (RB0) of

the16F876. This can be used to wake the microcontroller

from a low power sleep state after an interval of 1 to

100 seconds or 1 to 100 minutes. When the external

interrupt occurs, the handling routine clears the timer

flag on the PCF8583 and also reloads the PCF8583 timer

register with (100 - interval needed).

The Microchip 24LC256 IIC bus 256K bit

serial EEPROM can be used to store data for later

retrieval. More of these devices with different

addresses up to a total of eight can be added by

connecting them externally. Other IIC bus devices such

as an lcd display can be added by connecting them to the

IIC bus connector.

There are jumpers to either connect a

device permanently to +5V or to have it powered by bit

RC5 only when required. For example, the MAX232 consumes

about 10mA, but can be powered only when data is to be

sent out.

The MAX666 micropower +5V regulator has

a /LOBAT output that is connected to pin RB1 to flag a

flat battery. In addition the battery voltage can be

monitored and output in the data if needed.

A high value resistive divider is

buffered by an op. amp. that is connected to pin RA0,

A/D input 0. The op. amp. is needed because to maintain

10 bit accuracy there a 10k ohm inpedance limit on the

A/D input and low value resistors would consume too much

power. If the LM324 op. amp. is omitted a compromise is

possible using 100k ohm and 47k ohm resistors because

only low precision measurement to 0.1V is needed.

The measurement is only valid down to 7V

because below that the MAX666 regulator drops out, and

the A/D reference is +5V. Below 7V the /LOBAT signal

should be used to flag invalid data. The program adds

0.7V to compensate for the reverse voltage protection

diode D1.

PWM can be output if needed, to control

a pump motor for example. An analog output can be

derived by filtering the PWM1 output with R12 and C12.

RB2 is brought out to a pin as a control

bit. For example it can be used to turn on a pump to add

water to a tank when the level falls below a level set

in software. Variables like this and the probe

calibration constant can be stored in the EEPROM area of

the 16F876.

|