|

This is an easy to build, but

nevertheless very accurate and useful digital voltmeter.

It has been designed as a panel meter and can be used in

DC power supplies or anywhere else it is necessary to

have an accurate indication of the voltage present. The

circuit employs the ADC (Analogue to Digital Converter)

I.C. CL7107 made by INTERSIL. This IC incorporates in a

40 pin case all the circuitry necessary to convert an

analogue signal to digital and can drive a series of

four seven segment LED displays directly. The circuits

built into the IC are an analogue to digital converter,

a comparator, a clock, a decoder and a seven segment LED

display driver. The circuit as it is described here can

display any DC voltage in the range of 0-1999 Volts.

Supply Voltage: ............. +/- 5 V (Symmetrical)

Power requirements: ..... 200 mA (maximum)

Measuring range: .......... +/- 0-1,999 VDC in four ranges

Accuracy: ....................... 0.1 %

- Small size

- Easy construction

- Low cost.

- Simple adjustment.

- Easy to read from a distance.

- Few external components.

In order to understand the principle of

operation of the circuit it is necessary to explain how

the ADC IC works. This IC has the following very

important features:

- Great accuracy.

- It is not affected by noise.

- No need for a sample and hold circuit.

- It has a built-in clock.

- It has no need for high accuracy

external components.

Schematic (fixed 22-2-04)

7-segment display pinout MAN6960

An Analogue to Digital Converter, (ADC

from now on) is better known as a dual slope converter

or integrating converter. This type of converter is

generally preferred over other types as it offers

accuracy, simplicity in design and a relative

indifference to noise which makes it very reliable. The

operation of the circuit is better understood if it is

described in two stages. During the first stage and for

a given period the input voltage is integrated, and in

the output of the integrator at the end of this period,

there is a voltage which is directly proportional to the

input voltage. At the end of the preset period the

integrator is fed with an internal reference voltage and

the output of the circuit is gradually reduced until it

reaches the level of the zero reference voltage. This

second phase is known as the negative slope period and

its duration depends on the output of the integrator in

the first period. As the duration of the first operation

is fixed and the length of the second is variable it is

possible to compare the two and this way the input

voltage is in fact compared to the internal reference

voltage and the result is coded and is send to the

display.

All this sounds quite easy but it is in

fact a series of very complex operations which are all

made by the ADC IC with the help of a few external

components which are used to configure the circuit for

the job. In detail the circuit works as follows. The

voltage to be measured is applied across points 1 and 2

of the circuit and through the circuit R3, R4 and C4 is

finally applied to pins 30 and 31 of the IC. These are

the input of the IC as you can see from its diagram. (IN

HIGH & IN LOW respectively). The resistor R1 together

with C1 are used to set the frequency of the internal

oscillator (clock) which is set at about 48 Hz. At this

clock rate there are about three different readings per

second. The capacitor C2 which is connected between pins

33 and 34 of the IC has been selected to compensate for

the error caused by the internal reference voltage and

also keeps the display steady. The capacitor C3 and the

resistor R5 are together the circuit that does the

integration of the input voltage and at the same time

prevent any division of the input voltage making the

circuit faster and more reliable as the possibility of

error is greatly reduced. The capacitor C5 forces the

instrument to display zero when there is no voltage at

its input. The resistor R2 together with P1 are used to

adjust the instrument during set-up so that it displays

zero when the input is zero. The resistor R6 controls

the current that is allowed to flow through the displays

so that there is sufficient brightness with out damaging

them. The IC as we have already mentioned above is

capable to drive four common anode LED displays. The

three rightmost displays are connected so that they can

display all the numbers from 0 to 9 while the first from

the left can only display the number 1 and when the

voltage is negative the �-� sign. The whole circuit

operates from a symmetrical ρ 5 VDC supply which is

applied at pins 1 (+5 V), 21 (0 V) and 26 (-5 V) of the

IC.

First of all let us consider a few

basics in building electronic circuits on a printed

circuit board. The board is made of a thin insulating

material clad with a thin layer of conductive copper

that is shaped in such a way as to form the necessary

conductors between the various components of the

circuit. The use of a properly designed printed circuit

board is very desirable as it speeds construction up

considerably and reduces the possibility of making

errors. To protect the board during storage from

oxidation and assure it gets to you in perfect condition

the copper is tinned during manufacturing and covered

with a special varnish that protects it from getting

oxidised and also makes soldering easier.

Soldering the components to the board is the only way to

build your circuit and from the way you do it depends

greatly your success or failure. This work is not very

difficult and if you stick to a few rules you should

have no problems. The soldering iron that you use must

be light and its power should not exceed the 25 Watts.

The tip should be fine and must be kept clean at all

times. For this purpose come very handy specially made

sponges that are kept wet and from time to time you can

wipe the hot tip on them to remove all the residues that

tend to accumulate on it.

DO NOT file or sandpaper a dirty or worn

out tip. If the tip cannot be cleaned, replace it. There

are many different types of solder in the market and you

should choose a good quality one that contains the

necessary flux in its core, to assure a perfect joint

every time.

DO NOT use soldering flux apart from

that which is already included in your solder. Too much

flux can cause many problems and is one of the main

causes of circuit malfunction. If nevertheless you have

to use extra flux, as it is the case when you have to

tin copper wires, clean it very thoroughly after you

finish your work.

In order to solder a component correctly

you should do the following:

- Clean the component leads with a small

piece of emery paper.

- Bend them at the correct distance from

the components body and insert the component in its

place on the board.

- You may find sometimes a component

with heavier gauge leads than usual, that are too thick

to enter in the holes of the p.c. board. In this case

use a mini drill to enlarge the holes slightly. Do not

make the holes too large as this is going to make

soldering difficult afterwards.

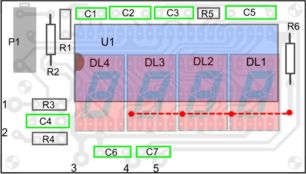

Parts placement

PCB dimensions: 77,6mm x 44,18mm or

scale it at 35%

- Take the hot iron and place its tip on

the component lead while holding the end of the solder

wire at the point where the lead emerges from the board.

The iron tip must touch the lead slightly above the p.c.

board.

- When the solder starts to melt and

flow wait till it covers evenly the area around the hole

and the flux boils and gets out from underneath the

solder. The whole operation should not take more than 5

seconds. Remove the iron and allow the solder to cool

naturally without blowing on it or moving the component.

If everything was done properly the surface of the joint

must have a bright metallic finish and its edges should

be smoothly ended on the component lead and the board

track. If the solder looks dull, cracked, or has the

shape of a blob then you have made a dry joint and you

should remove the solder (with a pump, or a solder wick)

and redo it.

- Take care not to overheat the tracks

as it is very easy to lift them from the board and break

them.

- When you are soldering a sensitive

component it is good practice to hold the lead from the

component side of the board with a pair of long-nose

pliers to divert any heat that could possibly damage the

component.

- Make sure that you do not use more

solder than it is necessary as you are running the risk

of short-circuiting adjacent tracks on the board,

especially if they are very close together.

- When you finish your work, cut off the

excess of the component leads and clean the board

thoroughly with a suitable solvent to remove all flux

residues that may still remain on it.

As it is recommended start working by

identifying the components and separating them in

groups. There are two points in the construction of this

project that you should observe:

First of all the display ICs are placed

from the copper side of the board and second the jumper

connection which is marked by a dashed line on the

component side at the same place where the displays are

located is not a single jumper but it should be changed

according to the use of the instrument. This jumper is

used to control the decimal point of the display.

If you are going to use the instrument

for only one range you can make the jumper connection

between the rightmost hole on the board and the one

corresponding to the desired position for the decimal

point for your particular application. If you are

planning to use the voltmeter in different ranges you

should use a single pole three position switch to shift

the decimal point to the correct place for the range of

measurement selected. (This switch could preferably be

combined with the switch that is used to actually change

the sensitivity of the instrument).

Apart from this consideration, and the

fact that the small size of the board and the great

number of joints on it which calls for a very fine

tipped soldering iron, the construction of the project

is very straightforward.

Insert the IC socket and solder it in

place, solder the pins, continue with the resistors the

capacitors and the multi-turn trimmer P1. Turn the board

over and very carefully solder the display ICs from the

copper side of the board. Remember to inspect the joints

of the base of the IC as one row will be covered by the

displays and will be impossible to see any mistake that

you may have made after you have soldered the displays

into place.

The value of R3 controls in fact the

range of measurement of the voltmeter and if you provide

for some means to switch different resistors in its

place you can use the instrument over a range of

voltages.

For the replacement resistors follow the

table below:

0 - 2 V ............ R3 = 0 ohm 1%

0 - 20 V ........... R3 = 1.2 Kohm 1%

0 - 200 V .......... R3 = 12 Kohm 1%

0 - 2000 V ......... R3 = 120 Kohm 1%

When you have finished all the soldering

on the board and you are sure that everything is OK you

can insert the IC in its place. The IC is CMOS and is

very sensitive to static electricity. It comes wrapped

in aluminium foil to protect it from static discharges

and it should be handled with great care to avoid

damaging it. Try to avoid touching its pins with your

hands and keep the circuit and your body at ground

potential when you insert it in its place.

Connect the circuit to a suitable power

supply ρ 5 VDC and turn the supply on. The displays

should light immediately and should form a number. Short

circuit the input (0 V) and adjust the trimmer P1 until

the display indicates exactly �0�.

R1 = 180k

P1 = 20k trimmer multi turn

R2 = 22k

U1 = ICL 7107

R3 = 12k

LD1,2,3,4 = MAN 6960 common

anode led displays

R4 = 1M

R5 = 470k

R6 = 560 Ohm

C1 = 100pF

C2, C6, C7 = 100nF

C3 = 47nF

C4 = 10nF

C5 = 220nF

Check your work for possible dry joints,

bridges across adjacent tracks or soldering flux

residues that usually cause problems.

Check again all the external connections

to and from the circuit to see if there is a mistake

there.

- See that there are no components

missing or inserted in the wrong places.

- Make sure that all the polarised

components have been soldered the right way round. -

Make sure the supply has the correct voltage and is

connected the right way round to your circuit.

- Check your project for faulty or

damaged components.

|