Three-phase power systems

Split-phase power systems achieve their high

conductor efficiency and low safety risk by splitting

up the total voltage into lesser parts and powering multiple

loads at those lesser voltages, while drawing currents at

levels typical of a full-voltage system. This technique, by

the way, works just as well for DC power systems as it does

for single-phase AC systems. Such systems are usually

referred to as three-wire systems rather than

split-phase because "phase" is a concept restricted to

AC.

But we know from our experience with vectors

and complex numbers that AC voltages don't always add up as

we think they would if they are out of phase with each

other. This principle, applied to power systems, can be put

to use to make power systems with even greater conductor

efficiencies and lower shock hazard than with split-phase.

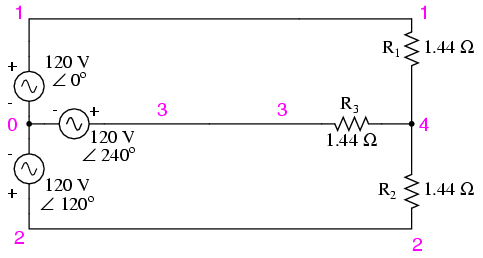

Suppose that we had two sources of AC

voltage connected in series just like the split-phase system

we saw before, except that each voltage source was 120o

out of phase with the other:

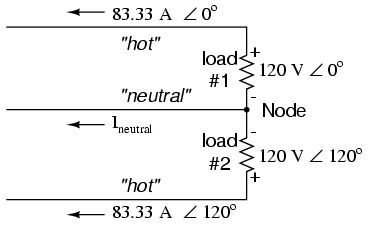

Since each voltage source is 120 volts, and

each load resistor is connected directly in parallel with

its respective source, the voltage across each load must

be 120 volts as well. Given load currents of 83.33 amps,

each load must still be dissipating 10 kilowatts of power.

However, voltage between the two "hot" wires is not 240

volts (120 ∠ 0o - 120 ∠ 180o) because

the phase difference between the two sources is not 180o.

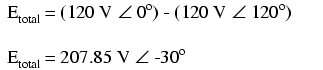

Instead, the voltage is:

Nominally, we say that the voltage between

"hot" conductors is 208 volts (rounding up), and thus the

power system voltage is designated as 120/208.

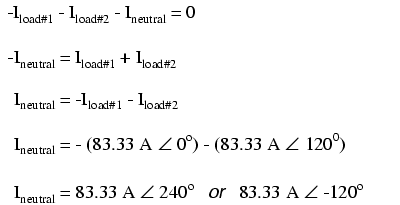

If we calculate the current through the

"neutral" conductor, we find that it is not zero,

even with balanced load resistances. Kirchhoff's Current Law

tells us that the currents entering and exiting the node

between the two loads must be zero:

So, we find that the "neutral" wire is

carrying a full 83.33 amps, just like each "hot" wire.

Note that we are still conveying 20 kW of

total power to the two loads, with each load's "hot" wire

carrying 83.33 amps as before. With the same amount of

current through each "hot" wire, we must use the same gage

copper conductors, so we haven't reduced system cost over

the split-phase 120/240 system. However, we have realized a

gain in safety, because the overall voltage between the two

"hot" conductors is 32 volts lower than it was in the

split-phase system (208 volts instead of 240 volts).

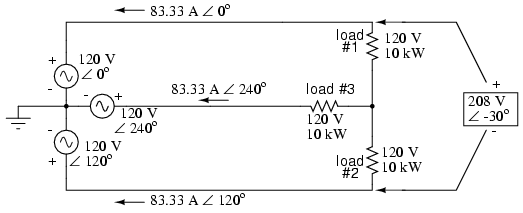

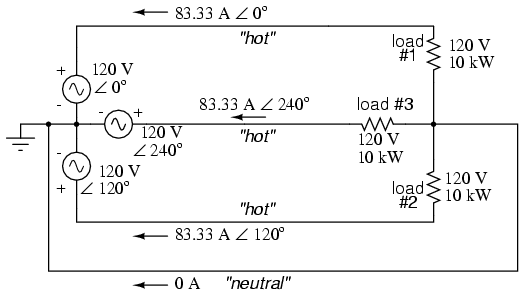

The fact that the neutral wire is carrying

83.33 amps of current raises an interesting possibility:

since it's carrying current anyway, why not use that third

wire as another "hot" conductor, powering another load

resistor with a third 120 volt source having a phase angle

of 240o? That way, we could transmit more

power (another 10 kW) without having to add any more

conductors. Let's see how this might look:

A full mathematical analysis of all the

voltages and currents in this circuit would necessitate the

use of a network theorem, the easiest being the

Superposition Theorem. I'll spare you the long, drawn-out

calculations because you should be able to intuitively

understand that the three voltage sources at three different

phase angles will deliver 120 volts each to a balanced triad

of load resistors. For proof of this, we can use SPICE to do

the math for us:

120/208 polyphase power system

v1 1 0 ac 120 0 sin

v2 2 0 ac 120 120 sin

v3 3 0 ac 120 240 sin

r1 1 4 1.44

r2 2 4 1.44

r3 3 4 1.44

.ac lin 1 60 60

.print ac v(1,4) v(2,4) v(3,4)

.print ac v(1,2) v(2,3) v(3,1)

.print ac i(v1) i(v2) i(v3)

.end

VOLTAGE ACROSS EACH LOAD

freq v(1,4) v(2,4) v(3,4)

6.000E+01 1.200E+02 1.200E+02 1.200E+02

VOLTAGE BETWEEN "HOT" CONDUCTORS

freq v(1,2) v(2,3) v(3,1)

6.000E+01 2.078E+02 2.078E+02 2.078E+02

CURRENT THROUGH EACH VOLTAGE SOURCE

freq i(v1) i(v2) i(v3)

6.000E+01 8.333E+01 8.333E+01 8.333E+01

Sure enough, we get 120 volts across each

load resistor, with (approximately) 208 volts between any

two "hot" conductors and conductor currents equal to 83.33

amps. At that current and voltage, each load will be

dissipating 10 kW of power. Notice that this circuit has no

"neutral" conductor to ensure stable voltage to all loads if

one should open. What we have here is a situation similar to

our split-phase power circuit with no "neutral" conductor:

if one load should happen to fail open, the voltage drops

across the remaining load(s) will change. To ensure load

voltage stability in the even of another load opening, we

need a neutral wire to connect the source node and load node

together:

So long as the loads remain balanced (equal

resistance, equal currents), the neutral wire will not have

to carry any current at all. It is there just in case one or

more load resistors should fail open (or be shut off through

a disconnecting switch).

This circuit we've been analyzing with three

voltage sources is called a polyphase circuit. The

prefix "poly" simply means "more than one," as in "polytheism"

(belief in more than one deity), polygon" (a

geometrical shape made of multiple line segments: for

example, pentagon and hexagon), and "polyatomic"

(a substance composed of multiple types of atoms). Since the

voltage sources are all at different phase angles (in this

case, three different phase angles), this is a "polyphase"

circuit. More specifically, it is a three-phase circuit,

the kind used predominantly in large power distribution

systems.

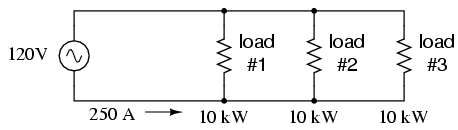

Let's survey the advantages of a three-phase

power system over a single-phase system of equivalent load

voltage and power capacity. A single-phase system with three

loads connected directly in parallel would have a very high

total current (83.33 times 3, or 250 amps:

This would necessitate 3/0 gage copper wire

(very large!), at about 510 pounds per thousand feet,

and with a considerable price tag attached. If the distance

from source to load was 1000 feet, we would need over a

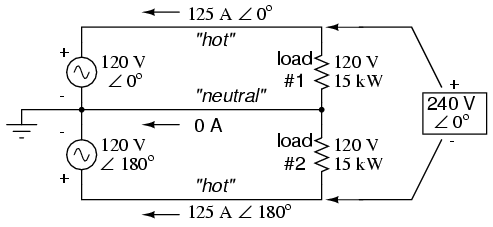

half-ton of copper wire to do the job. On the other hand, we

could build a split-phase system with two 15 kW, 120 volt

loads:

Our current is half of what it was with the

simple parallel circuit, which is a great improvement. We

could get away with using number 2 gage copper wire at a

total mass of about 600 pounds, figuring about 200 pounds

per thousand feet with three runs of 1000 feet each between

source and loads. However, we also have to consider the

increased safety hazard of having 240 volts present in the

system, even though each load only receives 120 volts.

Overall, there is greater potential for dangerous electric

shock to occur.

When we contrast these two examples against

our three-phase system, the advantages are quite clear.

First, the conductor currents are quite a bit less (83.33

amps versus 125 or 250 amps), permitting the use of much

thinner and lighter wire. We can use number 4 gage wire at

about 125 pounds per thousand feet, which will total 500

pounds (four runs of 1000 feet each) for our example

circuit. This represents a significant cost savings over the

split-phase system, with the additional benefit that the

maximum voltage in the system is lower (208 versus 240).

One question remains to be answered: how in

the world do we get three AC voltage sources whose phase

angles are exactly 120o apart? Obviously we can't

center-tap a transformer or alternator winding like we did

in the split-phase system, since that can only give us

voltage waveforms that are either in phase or 180o

out of phase. Perhaps we could figure out some way to use

capacitors and inductors to create phase shifts of 120o,

but then those phase shifts would depend on the phase angles

of our load impedances as well (substituting a capacitive or

inductive load for a resistive load would change

everything!).

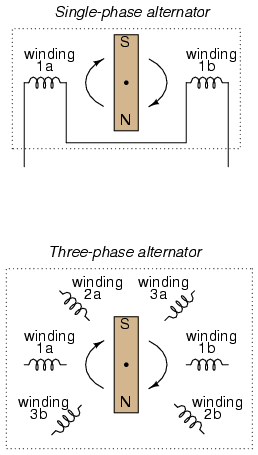

The best way to get the phase shifts we're

looking for is to generate it at the source: construct the

AC generator (alternator) providing the power in such a way

that the rotating magnetic field passes by three sets of

wire windings, each set spaced 120o apart around

the circumference of the machine:

Together, the six "pole" windings of a

three-phase alternator are connected to comprise three

winding pairs, each pair producing AC voltage with a phase

angle 120o shifted from either of the other two

winding pairs. The interconnections between pairs of

windings (as shown for the single-phase alternator: the

jumper wire between windings 1a and 1b) have been omitted

from the three-phase alternator drawing for simplicity.

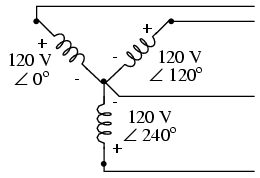

In our example circuit, we showed the three

voltage sources connected together in a "Y" configuration

(sometimes called the "star" configuration), with one lead

of each source tied to a common point (the node where we

attached the "neutral" conductor). The common way to depict

this connection scheme is to draw the windings in the shape

of a "Y" like this:

The "Y" configuration is not the only option

open to us, but it is probably the easiest to understand at

first. More to come on this subject later in the chapter.

-

REVIEW:

-

A single-phase power system is one

where there is only one AC voltage source (one source

voltage waveform).

-

A split-phase power system is one

where there are two voltage sources, 180o

phase-shifted from each other, powering a two

series-connected loads. The advantage of this is the

ability to have lower conductor currents while maintaining

low load voltages for safety reasons.

-

A polyphase power system uses

multiple voltage sources at different phase angles from

each other (many "phases" of voltage waveforms at work). A

polyphase power system can deliver more power at less

voltage with smaller-gage conductors than single- or

split-phase systems.

-

The phase-shifted voltage sources

necessary for a polyphase power system are created in

alternators with multiple sets of wire windings. These

winding sets are spaced around the circumference of the

rotor's rotation at the desired angle(s).

|