Voltmeter design

As was stated earlier, most meter movements

are sensitive devices. Some D'Arsonval movements have

full-scale deflection current ratings as little as 50 �A,

with an (internal) wire resistance of less than 1000 Ω. This

makes for a voltmeter with a full-scale rating of only 50

millivolts (50 �A X 1000 Ω)! In order to build voltmeters

with practical (higher voltage) scales from such sensitive

movements, we need to find some way to reduce the measured

quantity of voltage down to a level the movement can handle.

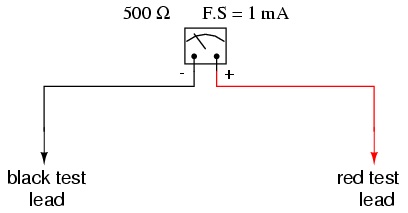

Let's start our example problems with a

D'Arsonval meter movement having a full-scale deflection

rating of 1 mA and a coil resistance of 500 Ω:

Using Ohm's Law (E=IR), we can determine how

much voltage will drive this meter movement directly to full

scale:

E = I R

E = (1 mA)(500 Ω)

E = 0.5 volts

If all we wanted was a meter that could

measure 1/2 of a volt, the bare meter movement we have here

would suffice. But to measure greater levels of voltage,

something more is needed. To get an effective voltmeter

meter range in excess of 1/2 volt, we'll need to design a

circuit allowing only a precise proportion of measured

voltage to drop across the meter movement. This will extend

the meter movement's range to being able to measure higher

voltages than before. Correspondingly, we will need to

re-label the scale on the meter face to indicate its new

measurement range with this proportioning circuit connected.

But how do we create the necessary

proportioning circuit? Well, if our intention is to allow

this meter movement to measure a greater voltage than

it does now, what we need is a voltage divider

circuit to proportion the total measured voltage into a

lesser fraction across the meter movement's connection

points. Knowing that voltage divider circuits are built from

series resistances, we'll connect a resistor in

series with the meter movement (using the movement's own

internal resistance as the second resistance in the

divider):

The series resistor is called a "multiplier"

resistor because it multiplies the working range of

the meter movement as it proportionately divides the

measured voltage across it. Determining the required

multiplier resistance value is an easy task if you're

familiar with series circuit analysis.

For example, let's determine the necessary

multiplier value to make this 1 mA, 500 Ω movement read

exactly full-scale at an applied voltage of 10 volts. To do

this, we first need to set up an E/I/R table for the two

series components:

Knowing that the movement will be at

full-scale with 1 mA of current going through it, and that

we want this to happen at an applied (total series circuit)

voltage of 10 volts, we can fill in the table as such:

There are a couple of ways to determine the

resistance value of the multiplier. One way is to determine

total circuit resistance using Ohm's Law in the "total"

column (R=E/I), then subtract the 500 Ω of the movement to

arrive at the value for the multiplier:

Another way to figure the same value of

resistance would be to determine voltage drop across the

movement at full-scale deflection (E=IR), then subtract that

voltage drop from the total to arrive at the voltage across

the multiplier resistor. Finally, Ohm's Law could be used

again to determine resistance (R=E/I) for the multiplier:

Either way provides the same answer (9.5 kΩ),

and one method could be used as verification for the other,

to check accuracy of work.

With exactly 10 volts applied between the

meter test leads (from some battery or precision power

supply), there will be exactly 1 mA of current through the

meter movement, as restricted by the "multiplier" resistor

and the movement's own internal resistance. Exactly 1/2 volt

will be dropped across the resistance of the movement's wire

coil, and the needle will be pointing precisely at

full-scale. Having re-labeled the scale to read from 0 to 10

V (instead of 0 to 1 mA), anyone viewing the scale will

interpret its indication as ten volts. Please take note that

the meter user does not have to be aware at all that the

movement itself is actually measuring just a fraction of

that ten volts from the external source. All that matters to

the user is that the circuit as a whole functions to

accurately display the total, applied voltage.

This is how practical electrical meters are

designed and used: a sensitive meter movement is built to

operate with as little voltage and current as possible for

maximum sensitivity, then it is "fooled" by some sort of

divider circuit built of precision resistors so that it

indicates full-scale when a much larger voltage or current

is impressed on the circuit as a whole. We have examined the

design of a simple voltmeter here. Ammeters follow the same

general rule, except that parallel-connected "shunt"

resistors are used to create a current divider

circuit as opposed to the series-connected voltage

divider "multiplier" resistors used for voltmeter

designs.

Generally, it is useful to have multiple

ranges established for an electromechanical meter such as

this, allowing it to read a broad range of voltages with a

single movement mechanism. This is accomplished through the

use of a multi-pole switch and several multiplier resistors,

each one sized for a particular voltage range:

The five-position switch makes contact with

only one resistor at a time. In the bottom (full clockwise)

position, it makes contact with no resistor at all,

providing an "off" setting. Each resistor is sized to

provide a particular full-scale range for the voltmeter, all

based on the particular rating of the meter movement (1 mA,

500 Ω). The end result is a voltmeter with four different

full-scale ranges of measurement. Of course, in order to

make this work sensibly, the meter movement's scale must be

equipped with labels appropriate for each range.

With such a meter design, each resistor

value is determined by the same technique, using a known

total voltage, movement full-scale deflection rating, and

movement resistance. For a voltmeter with ranges of 1 volt,

10 volts, 100 volts, and 1000 volts, the multiplier

resistances would be as follows:

Note the multiplier resistor values used for

these ranges, and how odd they are. It is highly unlikely

that a 999.5 kΩ precision resistor will ever be found in a

parts bin, so voltmeter designers often opt for a variation

of the above design which uses more common resistor values:

With each successively higher voltage range,

more multiplier resistors are pressed into service by the

selector switch, making their series resistances add for the

necessary total. For example, with the range selector switch

set to the 1000 volt position, we need a total multiplier

resistance value of 999.5 kΩ. With this meter design, that's

exactly what we'll get:

RTotal = R4 + R3

+ R2 + R1

RTotal = 900 kΩ + 90 kΩ + 9 kΩ +

500 Ω

RTotal = 999.5 kΩ

The advantage, of course, is that the

individual multiplier resistor values are more common (900k,

90k, 9k) than some of the odd values in the first design

(999.5k, 99.5k, 9.5k). From the perspective of the meter

user, however, there will be no discernible difference in

function.

|